It is widely recognized that achieving high energy storage density and efficiency in ferroelectric ceramics relies on their ability to exhibit high saturation polarization and low residual polarization, which are essential for excellent energy storage performance. Moreover, the enhancement of energy storage density in relaxor ferroelectric ceramics also requires a higher breakdown field strength, an important factor that should not be overlooked.

Tungsten-bronze (TB) structured ferroelectric ceramics possess unique structural characteristics, abundant compositional regulation mechanisms, and the capability to induce relaxation behavior easily. These attributes enable them to achieve significantly higher polarization values at lower electric field strengths, thereby greatly impacting their energy storage performance and expanding their applications in the field of energy storage.

Consequently, it is imperative to investigate strategies for attaining exceptional energy storage performance in tungsten-bronze structured ferroelectric ceramics.

A research team has now published a paper on this topic in the Journal of Advanced Ceramics.

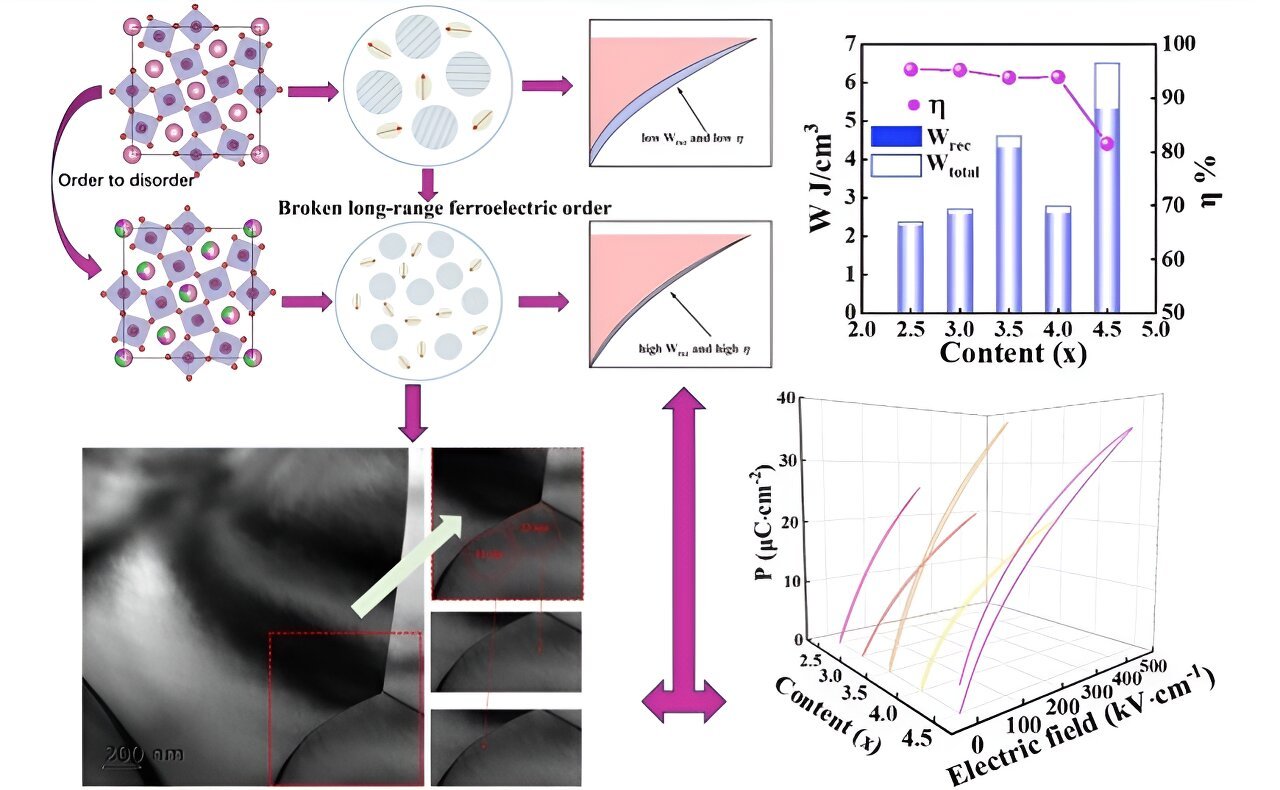

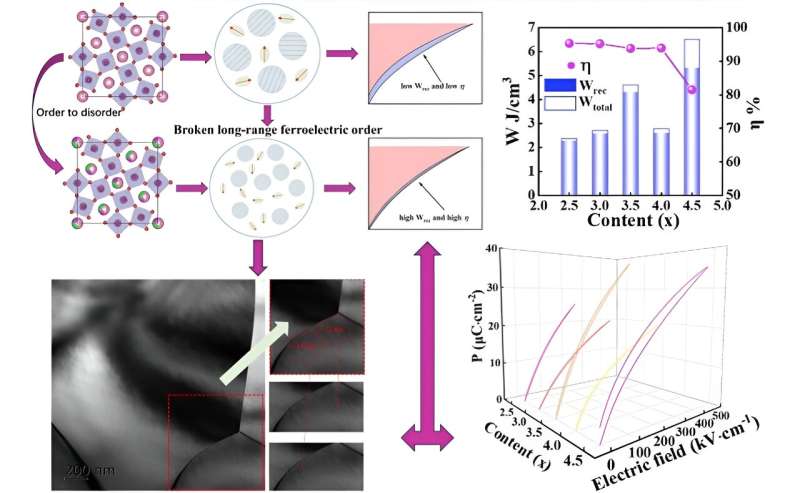

“In this report, we prepared Tetragonal TB Sr4.5-xBaxSm0.5Zr0.5Nb9.5O30 (x = 2.5, 3, 3.5, 4, 4.5)(SBSZN) ceramics using the strategy of co-doping with Ba2+, Sr2+, Sm3+ in the A-site and Zr4+ instead of Nb5+ in the B-site in order to break the ferroelectric long-range ordering, and confirmed the presence of polar nanoregions (PNRs) by high-resolution transmission electron microscopy, confirmed that the small-sized PNRs are intrinsic to induce the relaxation ferroelectric behavior of SBSZN ceramics,” said Changzheng Hu, professor at College of Materials Science and Engineering, Guilin University of Technology (China), mainly engaged in the research of ferroelectric, and tribocatalytic properties of tungsten-bronze structured ceramics.

“At the same time, it was observed by SEM that the grain size decreases with the increase of doping amount, and combined with the resistivity test, it was verified that the decrease of grain size caused a significant increase of resistivity, which led to the increase of the breakdown electric field strength,” said Prof. Hu.

The dielectric property tests revealed the typical temperature-dependent relaxation behavior of the dielectric constant and dielectric loss. It is worth noting that the x = 3.5 ceramic exhibits a Curie peak near room temperature, which can be attributed to its continuous compositional modulation. This unique property contributes significantly to an enhanced energy storage performance.

“Combining the Vogel-Fulcher empirical formula with the modified Curie-Weiss law and the Maxwell-Boltzmann distribution, it is analyzed through the dipole dynamics behavior that due to the small size of the PNRs, it is easier to cross the energy barrier and the weak coupling between the dipoles makes the dipole flip easier, thus leading to the relaxation behavior of SBSZN ceramics,” added Prof. Hu.

The elongated hysteresis loops observed in all ceramics during the ferroelectric tests can be attributed to the disruption of long-range ferroelectric ordering, which induces a relaxation-type ferroelectric behavior.

“The x = 3.5 ceramic has a high polarization due to the Curie temperature close to room temperature, while the small size of the PNRs gives them a low residual polarization, and thus they exhibit excellent energy storage performance by obtaining an energy storage density of 4.31 J·cm-3 and an efficiency of 93.8% at a breakdown field strength of 310 kV·cm-1,” said Hu.

Attributed to the significant decrease in grain size resulting in an increase in resistivity and therefore a significant enhancement of the breakdown field strength, the x = 4.5 ceramic also has excellent energy storage properties, resulting in a high energy storage density of 5.3 J·cm-3 at 460 kV·cm-1 and a high efficiency of 81.5 %.

“The significant difference in the size of the PNRs is responsible for the difference in efficiency between the two components of ceramics, with the x = 3.5 ceramic having PNRs sizes between 11 and 23 nm, and the x = 4.5 ceramic having PNRs sizes around 150 nm,” said Hu.

Furthermore, under over-damping conditions at a field strength of 400 kV·cm-1, the x = 3.5 ceramic exhibited excellent discharge performance, with a discharge energy density of up to 2.27 J·cm-3 within an extremely short discharge time (t0.9 ~ 34 ns). Additionally, remarkable charge/discharge performance characterized by CD = 713.38 A·cm-2 and PD = 87.51 MW·cm-3 was achieved under high under-damping conditions at a field strength of 240 kV·cm-1. Therefore, this work provides valuable insights into achieving high-performance energy storage properties even in low electric fields.

However, in order to enable tungsten-bronze structural ceramics to achieve a combination of superior energy storage properties, it is necessary to explore the potential for combining high polarization with low residual polarization at high electric field strengths. In this regard, Hu also suggests several possible directions for future investigation, including the development of composites with polymers and chalcogenides exhibiting high polarization values.

Other contributors include Yuejun Dan, Liupan Tang, Wenzhi Ning, Yingzhi Meng, Laijun Liu, Liang Fang from College of Materials Science and Engineering, Guilin University of Technology.

More information:

Yuejun Dan et al, Achieving enhanced energy storage performance and ultra-fast discharge time in tungsten–bronze ceramic, Journal of Advanced Ceramics (2024). DOI: 10.26599/JAC.2024.9220939

Provided by

Tsinghua University Press

Citation:

Achieving enhanced energy storage performance and ultra-fast discharge time in tungsten-bronze ceramic (2024, August 19)

retrieved 19 August 2024

from https://phys.org/news/2024-08-energy-storage-ultra-fast-discharge.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.