The ceramic produced in Prof. Igor Lubomirsky’s lab at the Weizmann Institute of Science seemed too good to be true. It belongs to a class of materials that are the backbone of many essential technologies but that unfortunately also create an environmental problem because they usually contain lead, which is highly toxic.

The surprising thing about the Weizmann ceramic was that it could perform just as well as other materials in this category while being entirely nontoxic. The research is published in the journal Nature Communications.

The new material falls into a class of substances that become deformed when exposed to an electric field, undergoing strains and stresses that are widely exploited in a slew of devices to produce tiny, precise movements.

In cell phones, for example, the slight deformation induced by voltage can set off the charging process or move the lens to create autofocus. In industrial inkjet printers, a plate buckles when voltage is applied, ejecting a controlled amount of ink.

At present, materials that undergo such deformations—they are known as electrostrictors or piezoelectrics, depending on the underlying mechanism—are a major source of lead pollution. Because electrostrictive and piezoelectric components tend to be too small to be recycled, tons of lead regularly end up in landfills.

Even though lead has been phased out from most other applications in the Western world, these materials are so indispensable that their use continues to be permitted. Piezoelectric materials, for example, constitute an annual global market of more than $20 billion.

Previous attempts by scientists around the world to produce lead-free electrostrictive or piezoelectric materials have been only marginally successful: Some are too chemically reactive, others too difficult to make. In contrast, the Weizmann substance—cerium oxide laced with about 10% zirconium oxide—is inert and simple to manufacture.

But perhaps its major potential advantage is that compared to materials currently in use, it can produce the same deformation while having a much lower dielectric constant, which means that it stores less electric charge—that is, it requires less energy to do the same work.

Moreover, the new ceramic’s source materials are cheap and readily available. Both cerium and zirconium are relatively abundant in Earth’s crust and are mined all over the planet for a variety of industrial applications. Cerium oxide, for example, is commonly used in powdered form to polish lenses and as a catalyst in catalytic converters, devices that reduce harmful emissions in cars.

The Weizmann ceramic might therefore offer an attractive and environmentally friendly alternative to existing electrostrictive or piezoelectric materials. But when, over a decade ago, Lubomirsky first started the research that would lead to its discovery, practical applications were far from his mind.

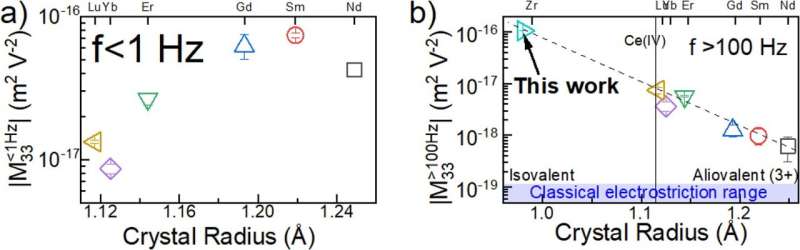

His team had discovered that under certain circumstances, the mechanical properties of cerium oxide—in pure form and when laced with impurities—didn’t fit the classical picture. The electrostrictive effect was about 100 times stronger than expected according to the predominant theory—still too tiny to be of practical use, but intriguing. The team continued to explore it.

About three years ago, Maxim Varenik, a Ph.D. student in Lubomirsky’s lab, performed an experiment that produced startling results. He introduced trivalent impurities—atoms with a chemical valence of three, that is, having three electrons in their outer orbit—into cerium. When he applied voltage to the resultant substances, he noticed an interesting, regular phenomenon: The smaller the inserted atoms were in size, the greater the electrostriction.

Because the increases in electrostriction had occurred along such a neat, straight line, he was curious to continue experimenting with ever smaller atoms. However, he ultimately ran out of trivalent impurities; none of the smaller ones he had already tried could be dissolved in cerium oxide.

Varenik then decided to introduce zirconium, the substance usually used in catalytic converters, even though it has four electrons in its outer orbit rather than three. To his and everyone else’s amazement, the electrostriction of the material he created didn’t move up by a notch, as had happened with the other experimental materials. Rather, it shot up about 200-fold.

“For about 10 years we’d studied something considered utterly useless—we did it for the sake of scientific curiosity,” Lubomirsky says. “Now we’ve suddenly obtained a material with potential engineering applications. The strains and stresses produced within it by voltage are on a par with those observed in the best commercial materials.”

In addition to exploring the properties that might make their ceramic attractive for industrial use, scientists in Lubomirsky’s lab are trying to explain why its electrostrictive performance was so far off the classical charts. “This is not an animal we’ve ever seen in our zoo,” Lubomirsky says.

Ever since discovering this nonclassical electrostriction, Lubomirsky’s team has been studying it in collaboration with Prof. Anatoly Frenkel of Stony Brook University, one of the world’s leading experts on a type of spectroscopy known as EXAFS. Recently, they were joined in this research by the theoretician Prof. Yue Qi of Brown University.

Their task, however, is far from being complete. “We still don’t fully understand what happens in this material,” Lubomirsky says, “but that’s precisely what makes it interesting.”

More information:

Maxim Varenik et al, Lead-free Zr-doped ceria ceramics with low permittivity displaying giant electrostriction, Nature Communications (2023). DOI: 10.1038/s41467-023-43032-5

Provided by

Weizmann Institute of Science

Citation:

Nontoxic ceramic could replace lead-based electronic components (2024, August 24)

retrieved 24 August 2024

from https://phys.org/news/2024-08-nontoxic-ceramic-based-electronic-components.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.